Description

Product Specifications

- Rating up to 17,000 RCF

- Sterile

- RNase-/DNase-free

- Nonpyrogenic

Materials:

Corning centrifuge tubes are available in two standard materials: polypropylene (PP) and polyethylene terephthalate (PET). Polypropylene tubes provide excellent chemical resistance and mechanical strength. They are strong, moderately rigid, and well-suited for most disposable centrifuge applications. PET tubes offer excellent optical clarity for ease of measurement, observation, and test recording.

Caps:

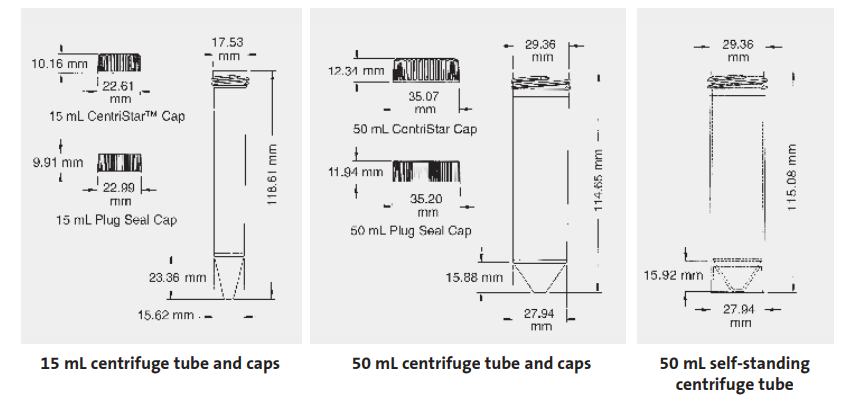

These tubes are available with two styles of polyethylene screw-top caps: the advanced Corning CentriStar™ cap and the original plug seal cap. The CentriStar cap has an easy-on/easy-off flat top and offers advanced ergonomics with its wider knurls and roll-over edge design for easier gripping. This leakproof design comes with a revolutionary plug feature that prevents seepage when used under recommended conditions. The plug seal cap is an original Corning design featuring a contoured plug for a tight, secure seal. This Corning plug seal product design has successfully passed the 95 kPa (14 psi) pressure test as referenced in IATA Dangerous Goods Regulations.

Dimensions of Corning® Centrifuge Tubes and Caps

Temperature Stability:

The recommended working temperature range for Corning centrifuge tubes is 0°C to 40°C. The suitability of these tubes for storage below 0°C depends on both the solution and the storage conditions. It is strongly recommended that a trial run be performed under actual conditions to test the suitability of the tubes for frozen storage. Do not freeze tubes using Corning® foam racks.

Chemical Compatibility:

The mechanical strength, flexibility, color, weight, and dimensional stability of all plastic centrifuge tubes are affected to varying degrees by the chemicals with which they come in contact. Specific operating conditions, especially temperature, relative centrifugal force (RCF), rotor type, carrier design, and run length will also affect tube performance. Always conduct a trial run to determine proper conditions before use.

Characteristics of Corning® Centrifuge Tubes

The following information is provided to serve as a general guideline for determining suitability of Corning centrifuge tubes for your applications. In addition, Corning recommends following the procedures outlined by the centrifuge manufacturer, as well as conducting a trial run to determine proper conditions before beginning any critical applications.

Corning centrifuge tubes are tested for leakage. They should not break or leak if used in a properly balanced rotor with suitable carriers, holders, and adapters that fully support the tubes when run in accordance with the guidelines in this section. These tubes are intended for one-time use only; reuse is not recommended as breakage or leakage may occur.

The recommended working temperature range for Corning centrifuge tubes is 0°C to 40°C. The suitability of these tubes for storage below 0°C depends on both the solution and the storage conditions. In general, the polypropylene and PET tubes are more resistant to stress at low temperatures than polystyrene. It is strongly recommended that a trial run be performed under actual conditions to test the suitability of the tubes for frozen storage.

Videos

View AllCloseWarranty Information

1 Review

-

low price

Received the tubes, very good quality and 10x lower in price than falcon 50 ml tubes.